Coating Laboratory:

6 coating chambers (cryo pumped and diffusion pumped)

Material deposited: Au, Al Cr, Ni, Rh, Pt, Ir, Os, MgF2, SIO2 24” apertures. Deposition sources-

Diamond Turning Laboratory:

5 single point diamond turning lathes. 36” plano apertures, curves, spheres. Materials, Al, Cu, ZnSe, Ge.

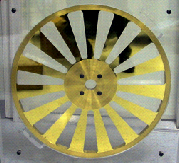

Ruling Laboratory:

6 Ruling engines. Each engine with its own dedicated temperature controlled room. Ruling engines are geared and sequenced for certain designs of diffraction gratings. Wavelength coverage and groove densities vary; Far IR to soft Xray

Line spacings:

7.2 millimeter per line/groove up to 7,200 lines per millimeter.

Blaze angles: 0.1º-

Substrate Dimensions:

Up to 1,000 x 1,000mm (40x40”)

Gratings:

- Type 1 Gratings, VLS gratings, Reflection and Transmission.

- IR gratings/ High Laser Damage threshold gratings-

on metal substrates - Invar, Cu etc. - Curved gratings for Hyperspectral applications -

Offner/ Dyson gratings. IR- UV - Fastest radius ~23mm convex / concave to Plano. Spheres and toroids - High line density gratings for UV-

Xray. Typically, 3,600 - 4,800 up to 7,200 l/mm

Original grating / Master grating:

Gratings ruled into a deposited metal film onto/ into a substrate of certain material.

Glass, ZnSe, CaF2, Al, Cu, Invar, Stainless Steels. Once a Master grating is

completed, we can make hundreds of replica copies from that Master.

Replicated Gratings:

The grating is replicated from a Master/ Original grating into an !epoxy film that is

over coated with a metallic coating for reflection or for transmission.

Testing Areas:

Multiple Lasers, HeNe, HeCd, Air tables.

Microscopes, Nomarski, Interference Microscopes, AFM

12” Zygo, Wyko, AFM profilers, Spectrometers, Angstrometers.